-

Plastic Injection Molding Parts

-

Medical Injection Molding Parts

-

Precision Injection Molding Parts

-

Metal Injection Molding Parts

-

Connector Mold Parts

-

Plastic Auto Parts Mould

-

Plastic Injection Machine Parts

-

Injection Molding Automotive Parts

-

Consumer Electronics Components

-

Mold Core Pins

-

Hot Runner Mould Parts

-

Standard Mould Parts

-

Miss JennyI am very satisfied with the quality and delivery time of your company and look forward to long-term cooperation in the future.

-

Mr.t HerryI have visited your company's machinery and testing equipment, and I feel very good. The sample has also been received, the polishing is very beautiful, very good!

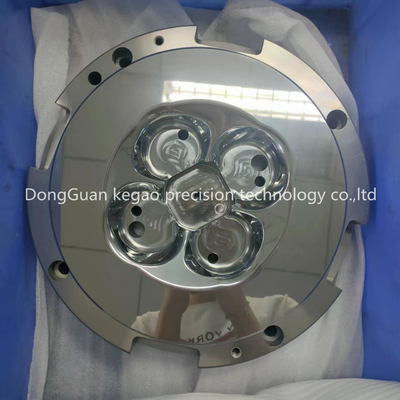

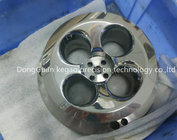

Mirror Polishing Wire Plastic Molding Parts for Cutting Machining

| Material | 1.2343 | HRC | 58-60 |

|---|---|---|---|

| Advertising | Plastic Molding Parts | Size | Make According To Drawings |

| Heat Treatment | Standard | Surface Treatment | DLC COATING |

| Export Country | Japan/USA/Europe | Payment Terms | Negotiable |

| High Light | 1.2343 Plastic Molding Parts,Plastic Molding Parts Mirror Polishing Wire,DLC COATING Plastic Injection Molding Parts |

||

MIRROR POLISHING WIRE CUTTING MACHINING MOULD PARTS WITH HIGHT QUALITY

Description:

| Parts Name: | MIRROR POLISHING WIRE CUTTING MACHINING MOULD PARTS WITH HIGHT QUALITY | Hardness: | 58-60 |

| Product size: | Customized/As Per Drawings | Grinding accuracy: | ±0.002mm |

|

|

Japan (SKD11.SKD61.SKH51.S45C) | Tolerance: | 0.01mm |

| USA (AISA.D2.H13.P20.M2) | EDM Accuracy: | ±0.003mm | |

| Germany (DIN.2379.2363.2344.2347) | Grind Clear Angle Max: | 0.02 | |

| ASSAB(Rigor.DIVEAR.Impax.Elmax.VANADIS4.STAVAX) | EDM Angle Max: | 0.02 | |

| Proce | GRIND→CNC→WIRE CUTTING | Grinding Finish Ra: | 0.2 |

| Application: | PLASTIC MOLD COMPONENTS | EDM Finish Ra: | 0.3 |

| Wire Cutting Finish Ra: | 0.3-0.4 | ||

| Processing flow: | Heat treatment →GRIND→ CNC→WIRE CUTTING→Quality inspection | ||

We pay special attention to materials and durability of the mould parts.Years of machining experiences,high-quality imported materials,advanced imported machining equipment, leading testing equipment, and perfect delivery quality management system ensure high-quality product components.

Why choose us

- We as a manufacturer are specialized in all kinds of precsion core pins cavity pins insert pins

- Good experience of 8 years to make Stamping die parts,Injection die parts,Auto parts, metal-working products.

- Have advanced production equipments and experienced operators.

- Good experience of OEM and ODM for our customers.

- Provide best price, good quality and fast delivery.

Payment Terms

T/T,Paypal,Western Union,50% deposit, balance before shipment is available

Package

Coated with anticorrosive oil, packed in carton box

Shipment ways

DHL,TNT,Fedex are available

Advantage

| (1) Highly polished finish 6-8 micro finish. |

| (2) Precision form ground to close diameter tolerance +/-0.005mm |

| (3) Common fractional sizes available up to 3 1/2″ long. |

| (4) M-2 high speed steel 60-63 Rockwell C. |

| (5) Custom sizes can be made to order up to 1″ diameter. |

| (6) Custom hardness RC 64-65 and triple drawn available on request. |

How to order?

(a) Please send us drawing or sample(non-standard parts) or series number(standard parts).

We can sign NDA if the file is belongs to intellectual property and confidential.

(b) We evaluate the drawing and requirement immediately.

(c) We try to send the offer at the same day back to customer.

(d) If we both agreed on the offer, for trade rules, we accept 50% Deposit before order, and 50% Balance when shipment is taking.Then we can start manufacturing or sample process.

(e) Our production time usually takes 10 working days,sample process takes 7 days. It depends on order quanity and product itself.

(f) We can ship the parts by express,air,sea according to your need.

I think a lot of items will match your interest,and really hope to establish business relationship with you!

Any questions,pls feel free to contact me at any time.

![]()

![]()

![]()