-

Plastic Injection Molding Parts

-

Medical Injection Molding Parts

-

Precision Injection Molding Parts

-

Metal Injection Molding Parts

-

Connector Mold Parts

-

Plastic Auto Parts Mould

-

Plastic Injection Machine Parts

-

Injection Molding Automotive Parts

-

Consumer Electronics Components

-

Mold Core Pins

-

Hot Runner Mould Parts

-

Standard Mould Parts

-

Miss JennyI am very satisfied with the quality and delivery time of your company and look forward to long-term cooperation in the future.

-

Mr.t HerryI have visited your company's machinery and testing equipment, and I feel very good. The sample has also been received, the polishing is very beautiful, very good!

Viking Material Medical Injection Molding Parts Polishing SPIA1 0.02 EDM

| Material | Viking | HRC | 58-60 |

|---|---|---|---|

| Advertising | Medical Molding | Size | Make According To Drawings |

| Polishing | SPI-A1 | Packaging Details | Wooden Box Package |

| Export Country | Japan/USA/Europe | Payment Terms | Negotiable |

| High Light | SPIA1 Medical Injection Molding Parts,0.02 EDM Medical Injection Molding Parts,Viking medical injection moulding |

||

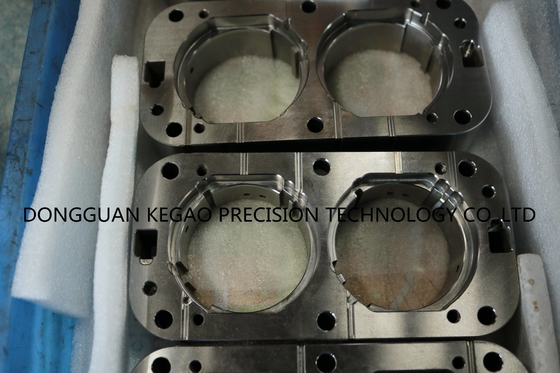

Core Main Insert For Medical Molding And Viking Material With Polishing SPIA1

Description:

| Parts Name: | Core Main Insert For Medical Molding And Viking Material With Polishing SPIA1 | Hardness: | 58-60HRC |

| Product size: | Customized/As Per Drawings | Grinding accuracy: | ±0.001mm |

|

|

Japan (SCM435.SKD61.SKH51.S45C) | Tolerance: | 0.001mm |

| USA (AISA.D2.H13.P20.M2) | EDM Accuracy: | ±0.003mm | |

| Germany (DIN.2379.2363.2344.2347) | Grind Clear Angle Max: | 0.02 | |

| ASSAB(Rigor.DIVEAR.Impax.Elmax.VANADIS4,Viking) | EDM Angle Max: | 0.02 | |

| Process: | NC→Grinding | Grinding Finish Ra: | 0.2 |

| Application: | Medical Molding | EDM Finish Ra: | 0.3 |

| Wire Cutting Finish Ra: | 0.3-0.4 | ||

| Processing flow: | Heat treatment →CNC→Wire Cutting →Grinding →Quality inspection | ||

Our adavanges:

1. Clean and tidy workshop.

2. Strick and serious manangement, skilled and expericenced technicians.

3. Various raw material(imported and Chinese) to meet different needs of customers.

4. Equipment of high pricision.( Surface grinding,Sodick Wire-cutting.drilling machine).

5. The QC go along with all the production processes in our factory.

6. You can use English or Japanese for cummunication.

Why choose us?

1. We as a manufacturer are specialized in all kinds of precsion core pins cavity pins insert pins

2. Good experience of 10 years to make Stamping die parts,Injection die parts,Auto parts, metal-working products.

3. Have advanced production equipments and experienced operators.

4. Good experience of OEM and ODM for our customers.

5. Provide best price, good quality and on-time delivery.

FAQ:

Where Is Your Factory Located? How Can I Visit There?

A: Our factory is located in dongguan city, chang'an town, which is near the shenzhen and hongkong, welcome to visit us at any time.

Are You A Factory Or A Trading Company?

A: We are factory over 15 years experience.

How Should I Start The Production Without 3D Drawing?

A: You can courier a sample to us, we will help you to finish the 3D drawing design.

Before Shipment How To Make Sure The Plastic Mould Parts Quality?

A: You can come to our factory or let the third party for inspection, if not, we will be as your inspection worker. we will share you a video for production process details.

When Can We Get The Price Of Plastic Mould Parts?

A: We usually quote the price within 24 hours after we get your inquiry. if it is very urgent, please call us.

If you have some questions about plastic moulds, or want to know more about auto mould parts, medical mould parts, packaging mould parts, cosmetic mould parts, connector mould parts etc. Welcome to contact us!

![]()

![]()

![]()