-

Plastic Injection Molding Parts

-

Medical Injection Molding Parts

-

Precision Injection Molding Parts

-

Metal Injection Molding Parts

-

Connector Mold Parts

-

Plastic Auto Parts Mould

-

Plastic Injection Machine Parts

-

Injection Molding Automotive Parts

-

Consumer Electronics Components

-

Mold Core Pins

-

Hot Runner Mould Parts

-

Standard Mould Parts

-

Miss JennyI am very satisfied with the quality and delivery time of your company and look forward to long-term cooperation in the future.

-

Mr.t HerryI have visited your company's machinery and testing equipment, and I feel very good. The sample has also been received, the polishing is very beautiful, very good!

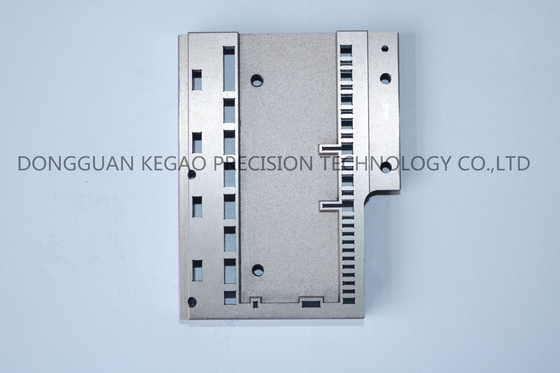

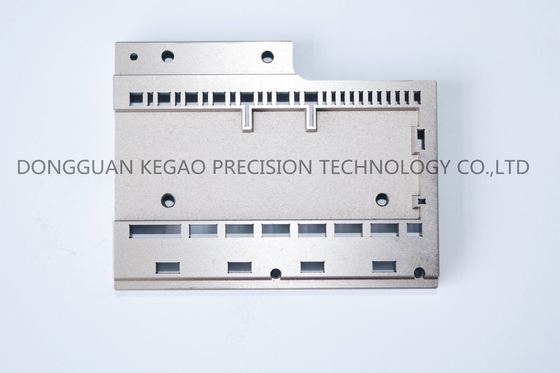

60HRC Prototype Injection Molding , Die Casting Components HSS SKH51 Material

| Material | SKH51 | HRC | 58-60 |

|---|---|---|---|

| Advertising | HSS SKH51 Material Hight Precision Connector Molding | Size | Make According To Drawings |

| Heat Treatment | Standard | Surface Treatment | Polishing |

| Export Country | Japan/USA/Europe | Payment Terms | Negotiable |

| High Light | Connector Mould Parts,WEDM Processing Mould Parts,Electronic Part |

||

HSS SKH51 Material Hight Precision Connector Molding With Hight Polishing

Description:

| Parts Name: | HSS SKH51 Material Hight Precision Connector Molding With Hight Polishing | Hardness: | 58-60 |

| Product size: | Customized/As Per Drawings | Grinding accuracy: | ±0.001mm |

|

|

Japan (SKD11.SKD61.SKH51.S45C) | Tolerance: | 0.001mm |

| USA (AISA.D2.H13.P20.M2) | EDM Accuracy: | ±0.003mm | |

| Germany (DIN.2379.2363.2344.2347) | Grind Clear Angle Max: | 0.02 | |

| ASSAB(Rigor.DIVEAR.Impax.Elmax.VANADIS4.STAVAX) | EDM Angle Max: | 0.02 | |

| Process: | Grinding→Wire Cutting→EDM | Grinding Finish Ra: | 0.2 |

| Application: | HSS SKH51 Material Hight Precision Connector Molding | EDM Finish Ra: | 0.3 |

| Wire Cutting Finish Ra: | 0.3-0.4 | ||

| Processing flow: | Heat treatment →Grinding→EDM→Quality inspection | ||

Further Information:

| Testing machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine,roughness tester, hardness tester and so on. |

| QC | 1) Technicians self-check in production |

| 2) Engineer spot check in production | |

| 3) QC inspects after mass production finished | |

| 4) International sales who were trained the technical know-how spot check before shipping | |

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe,South Europe, South Asia, Africa Africa |

Our Advantages:

Consistent Quality Control:

1.We have very experienced staffs can control the parts to exact dimensions in the process of production.

2.Our experienced QCs inspect all the parts thoroughly which can ensure 100% high quality products sent to you .

Pre-qualified machining Partners:

We’ve built a strong network of local and overseas partners for every project need.

Prototype to production:

Whether you need quick-turn prototypes in 7 days or 10,00 units at the right price, we have pre-qualified Manufacturing Partners who can deliver.

Hands-on quality management:

We're an ISO certified company and ensure every part is produced and inspected according to our detailed quality management system.

Service:

1. Team work-We have experienced engineers, programmers, QC, sales and management team. Every member is firmly connected to well fulfill customers' orders.

2. Skill–We hold skill explore training every month . Engineers, programmers and workers share new ideas and skills together to continuously improve machining skill.

Packing & Delivery

| Package | Coated with anticorrosive oil, packed in carton box with bubble wrap, together with QA report. |

| Express | DHL, FedEx, UPS, TNT,by Sea . |

Payment Terms:

Payment terms: T/T,Paypal,Western Union,50% deposit, balance before shipment is available

Shipment: DHL,TNT,Fedex are available

If you are interested, please do not hesitate to contact us! Thank you!

![]()

![]()