-

Plastic Injection Molding Parts

-

Medical Injection Molding Parts

-

Precision Injection Molding Parts

-

Metal Injection Molding Parts

-

Connector Mold Parts

-

Plastic Auto Parts Mould

-

Plastic Injection Machine Parts

-

Injection Molding Automotive Parts

-

Consumer Electronics Components

-

Mold Core Pins

-

Hot Runner Mould Parts

-

Standard Mould Parts

-

Miss JennyI am very satisfied with the quality and delivery time of your company and look forward to long-term cooperation in the future.

-

Mr.t HerryI have visited your company's machinery and testing equipment, and I feel very good. The sample has also been received, the polishing is very beautiful, very good!

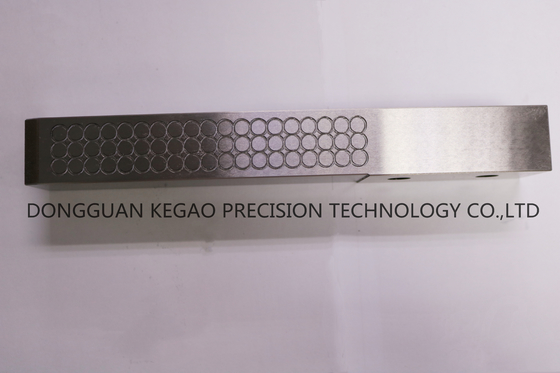

SKH51 Precision Injection Molding Parts Hight Polishing 0.001mm Tolerance

| Material | SKH51 | HRC | 60-62 |

|---|---|---|---|

| Advertising | Hight Precision Injection Molding Parts | Size | Make According To Drawings |

| Heat Treatment | Standard | Surface Treatment | Polishing |

| Export Country | Japan/USA/Europe | Payment Terms | Negotiable |

| High Light | SKH51 Precision Injection Molding Parts,0.001mm Precision Injection Molding Parts,SKH51 precision plastic products |

||

SKH51 And Hight Precision Injection Molding Parts With Hight Polishing

Description:

| Parts Name: | SKH51 And Hight Precision Injection Molding Parts With Hight Polishing | Hardness: | 58-60 |

| Product size: | Customized/As Per Drawings | Grinding accuracy: | ±0.001mm |

| Japan (SKD11.SKD61.SKH51.S45C) | Tolerance: | 0.001mm |

| USA (AISA.D2.H13.P20.M2) | EDM Accuracy: | ±0.003mm | |

| Germany (DIN.2379.2363.2344.2347) | Grind Clear Angle Max: | 0.02 | |

| ASSAB(Rigor.DIVEAR.Impax.Elmax.VANADIS4.STAVAX) | EDM Angle Max: | 0.02 | |

| Process: | Grinding→EDM | Grinding Finish Ra: | 0.2 |

| Application: | SKH51 And Hight Precision Injection Molding Parts | EDM Finish Ra: | 0.3 |

| Wire Cutting Finish Ra: | 0.3-0.4 | ||

| Processing flow: | Heat treatment →CNC→Grinding→EDM→Quality inspection | ||

Further Information:

| Testing machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine,roughness tester, hardness tester and so on. |

| QC | 1) Technicians self-check in production |

| 2) Engineer spot check in production | |

| 3) QC inspects after mass production finished | |

| 4) International sales who were trained the technical know-how spot check before shipping | |

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe,South Europe, South Asia, Africa Africa |

Advantages:

1. Good quality

Include machining, surface treatment, specification, packing, etc.

2. Proper suggestions

If you are not familiar with material, surface treatment or something, please tell us your requirement, according to which we will provide you with proper suggestions. Also, advice will be given during machining when your design is found not good enough. Anyway, it is finally up to you whether to adopt the suggestions.

Service:

1. Team work-We have experienced engineers, programmers, QC, sales and management team. Every member is firmly connected to well fulfill customers' orders.

2. Skill–We hold skill explore training every month . Engineers, programmers and workers share new ideas and skills together to continuously improve machining skill.

Business Range:

Manufacturing & inspection capacity in steel, stainless and copper materials for precision mould parts,Cavity pins, core pins,Punches,Ejector sleeve,CNC machining parts etc...

Services:CNC machining,CNC Milling,Sodick EDM,Sodick Wire-cut,OD grinding,ID grinding,Surface grinding,Thread grinding,Polishing etc..

Industries Served: Medical/Packaging/Aerospace/Electronic

If you are interested, please do not hesitate to contact us! Thank you!

![]()