-

Plastic Injection Molding Parts

-

Medical Injection Molding Parts

-

Precision Injection Molding Parts

-

Metal Injection Molding Parts

-

Connector Mold Parts

-

Plastic Auto Parts Mould

-

Plastic Injection Machine Parts

-

Injection Molding Automotive Parts

-

Consumer Electronics Components

-

Mold Core Pins

-

Hot Runner Mould Parts

-

Standard Mould Parts

-

Miss JennyI am very satisfied with the quality and delivery time of your company and look forward to long-term cooperation in the future.

-

Mr.t HerryI have visited your company's machinery and testing equipment, and I feel very good. The sample has also been received, the polishing is very beautiful, very good!

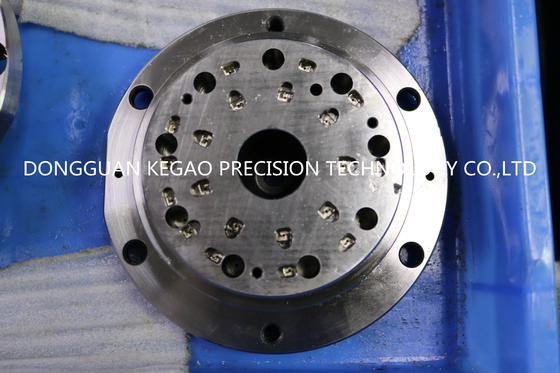

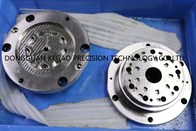

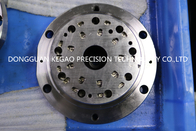

Ra0.4 Medical Injection Molding Parts , 8407 Multi Cavity Mould 0.005mm

| Material | 8407 | HRC | 48-52 |

|---|---|---|---|

| Advertising | Side Cavity For Hight Precision Medical Injection Molding | Size | Make According To Drawings |

| Heat Treatment | Standard | Surface Treatment | Polishing |

| Export Country | Japan/USA/Europe | Payment Terms | Negotiable |

| High Light | Ra0.4 Medical Injection Molding Parts,0.005mm Medical Injection Molding Parts,8407 multi cavity mould |

||

Side Cavity For Hight Precision Medical Injection Molding And 8407 Material

Description:

| Parts Name: | Side Cavity For Hight Precision Medical Injection Molding And 8407 Material | Hardness: | 48-52 |

| Product size: | Customized/As Per Drawings | Grinding accuracy: | ±0.001mm |

|

|

Japan (SKD11.SKD61.SKH51.S45C) | Tolerance: | 0.001mm |

| USA (AISA.D2.H13.P20.M2) | EDM Accuracy: | ±0.003mm | |

| Germany (DIN.2379.2363.2344.2347) | Grind Clear Angle Max: | 0.02 | |

| ASSAB(Rigor.DIVEAR.Impax.Elmax.VANADIS4.STAVAX) | EDM Angle Max: | 0.02 | |

| Proce | Grinding→ Wire Cutting→EDM | Grinding Finish Ra: | 0.2 |

| Application: | Side Cavity For Hight Precision Medical Injection Molding | EDM Finish Ra: | 0.3 |

| Wire Cutting Finish Ra: | 0.3-0.4 | ||

| Processing flow: | Heat treatment → Grinding→ Wire Cutting→EDM→Quality inspection | ||

Specification

1. Size tolerance within +/-0.003mm

2. Axiality within 0.005mm

3. Surface Roughness within Ra0.4

4. Verticality within 0.005mm

5. Further dimensions,lengths and materials available on request

Service

1. Team work-We have experienced engineers, programmers, QC, sales and management team. Every member is firmly connected to well fulfill customers' orders.

2. Skill–We hold skill explore training every month . Engineers, programmers and workers share new ideas and skills together to continuously improve machining skill.

3. Excellent communication – Sales members are fluent English speaking, proactive and have knowledge about machining, They can easily understand what you want.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are mould parts manufacturing, providing precision mould parts, die casting mold parts, plastic injection mould parts, machined parts, etc.

Q: How do you need to provide a quote?

A: Please kindly send us the drawing of you products. Details below should be included:

a. Materials

b. Surface finish

c.Tolerance

d. quantity

e.drawings (3D/CAD/2D drawing)

(Please be noted that these are essential for our quoting. We couldn't quote the specific price without any of them.)

Q: How do I know about the delivery?

A: We will inform you of the tracking number once we get it from shipping agent. Also we will keep updating the latest shipping information for you.

Fetures

| Materials | 8407 |

| Industry Standards | DIN, JIS, AISI, GB |

| Minimum Order Quantity (MOQ) | 1 piece |

| Production Capacity | 2000 pieces per week |

| Lead Time | 7-20 days from deposit |

| Payment Term | T/T, Paypal, Western Union, Cash |

| Quality control | Hardness tester, Callipers, Alitimeter, CMM, Projector, 2.5D |

| Machines/equipment | CNC lathes, OD Grinder, EDM, CNC Milling |

| Other Service | OEM &OEM, Customized Specification, One to One Communication, Free Samples |

| Additional | 1) Sample Order and Small Order are acceptable; 2) The methods of delivery: DHL,EMS,UPS or Fedex (fast and safer) 3) Located in manufacturing base of china-dongguan city,we also help customer design according to customers' requirements and products' application. |

I think a lot of items will match your interest,and really hope to establish business relationship with you!

Any questions,pls feel free to contact me at any time.

If you are interested, please do not hesitate to contact us! Thank you!

![]()