-

Plastic Injection Molding Parts

-

Medical Injection Molding Parts

-

Precision Injection Molding Parts

-

Metal Injection Molding Parts

-

Connector Mold Parts

-

Plastic Auto Parts Mould

-

Plastic Injection Machine Parts

-

Injection Molding Automotive Parts

-

Consumer Electronics Components

-

Mold Core Pins

-

Hot Runner Mould Parts

-

Standard Mould Parts

-

Miss JennyI am very satisfied with the quality and delivery time of your company and look forward to long-term cooperation in the future.

-

Mr.t HerryI have visited your company's machinery and testing equipment, and I feel very good. The sample has also been received, the polishing is very beautiful, very good!

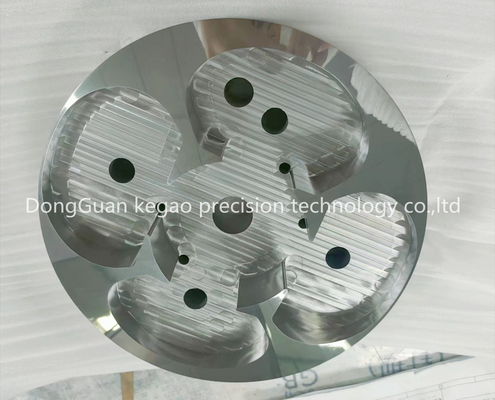

1.2343 Material Mirror Polishing Metal Injection Molding Parts With DLC Coating

| Material | 1.2343 | HRC | 58-60 |

|---|---|---|---|

| Advertising | METAL INJECTION MOLDING PARTS | Size | Make According To Drawings |

| Heat Treatment | Standard | Surface Treatment | DLC COATING |

| Export Country | Japan/USA/Europe | Payment Terms | Negotiable |

| High Light | DLC Coating Metal Injection Molding Parts,1.2343 Metal Injection Molding Parts,DLC Coating Metal Injection Molds |

||

1.2343 MATERIAL MIRROR POLISHING METAL INJECTION MOLDING PARTS WITH DLC COATING

Description:

| Parts Name: | 1.2343 MATERIAL MIRROR POLISHING METAL INJECTION MOLDING PARTS WITH DLC COATING | Hardness: | 58-60 |

| Product size: | Customized/As Per Drawings | Grinding accuracy: | ±0.002mm |

|

|

Japan (SKD11.SKD61.SKH51.S45C) | Tolerance: | 0.01mm |

| USA (AISA.D2.H13.P20.M2) | EDM Accuracy: | ±0.003mm | |

| Germany (DIN.2379.2363.2344.2347) | Grind Clear Angle Max: | 0.02 | |

| ASSAB(Rigor.DIVEAR.Impax.Elmax.VANADIS4.STAVAX) | EDM Angle Max: | 0.02 | |

| Proce | GRIND→CNC→WIRE CUTTING | Grinding Finish Ra: | 0.2 |

| Application: | PLASTIC MOLD COMPONENTS | EDM Finish Ra: | 0.3 |

| Wire Cutting Finish Ra: | 0.3-0.4 | ||

| Processing flow: | Heat treatment →GRIND→ CNC→WIRE CUTTING→Quality inspection | ||

Tolerance

+-0.005mm, Depends on customer’s requirements.

Drawing Format

PDF/DWG/DXF/IGS/STEP,etc

Packaging

Inner packing with recycle plastic box and anticorrosive oil, outer with sponge and PE bags, or as customer's requirements.

Application field

Automobile parts, medical, daily necessities packaging, cosmetic packaging, etc.

Sales team

Only with teamwork can leadership be maintained.

Team spirit is a company’s core competitiveness. Only team can lead the way, only strong team can go further.

Main products

SENLAN manufactures a full line of standard and customized ejector pins,punches,insert pins ,cavity pins,core pins,mold core, and other mould accessories and die parts etc.

Service

1. Providing professional advises and operation.

2. Customer service online with 24 hours.

3. Full inspection on all the products before shipment.

4. Good After-sale service.

5. Strict quality control.

6. Shipping & Price Term: EXW my factory; FOB any Chinese port; CIF any destination port.

7. OEM and ODM are all available.

FAQ

Q: What do you need to provide a quote?

A: Please kindly send us the drawing or sample of your product. Details below should be included,

1. Materials 2. Surface Finish 3. Tolerance 4. Quantity 5.other special requirements.

Q: How long is your delivery time?

A: It is 7-30 days produce an order from MOQ to 40HQ container. But the exact delivery time might be depend on different quantity.

Q: Do you provide samples ? Is it free or extra ?

A: Yes, we are honored to offer you samples or raw material for quality inspection,but do not pay the cost of freight.

Q: How does your factory do regarding quality control?

A: Quality is priority. Kegao always attach great importance to quality control from the very beginning to the end of the production.Before processing we need to test the material first. During the processing we use bar code to tracking the proceeding.We will make 100% inspection before packing and delivery to make sure the products 100% meet your requirements.We will keep the production drawing and test report with 3 months, if you found any problems when received the parts, please contact us at the first time, we will give you a solution within 8 hours.

![]()

![]()

![]()