-

Plastic Injection Molding Parts

-

Medical Injection Molding Parts

-

Precision Injection Molding Parts

-

Metal Injection Molding Parts

-

Connector Mold Parts

-

Plastic Auto Parts Mould

-

Plastic Injection Machine Parts

-

Injection Molding Automotive Parts

-

Consumer Electronics Components

-

Mold Core Pins

-

Hot Runner Mould Parts

-

Standard Mould Parts

-

Miss JennyI am very satisfied with the quality and delivery time of your company and look forward to long-term cooperation in the future.

-

Mr.t HerryI have visited your company's machinery and testing equipment, and I feel very good. The sample has also been received, the polishing is very beautiful, very good!

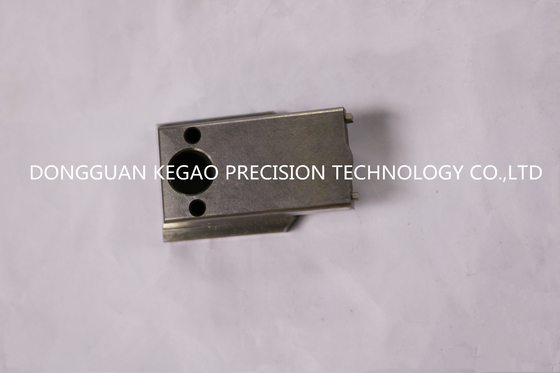

1.2767 Material Plastic Injection Machine Parts 0.001mm Tolerance

| Material | 1.2767 | HRC | 53-57HRC |

|---|---|---|---|

| Advertising | Hight Plastic Injection Machine Parts | Size | Make According To Drawings |

| Heat Treatment | Standard | Surface Treatment | Polishing |

| Export Country | Japan/USA/Europe | Payment Terms | Negotiable |

| High Light | 1.2767 Plastic Injection Machine Parts,0.001mm Plastic Injection Machine Parts,1.2767 molding machine parts |

||

1.2767 Material And Hight Plastic Injection Machine Parts With Polishing

Description:

| Parts Name: | 1.2767 Material And Hight Plastic Injection Machine Parts With Polishing | Hardness: | 53-57 |

| Product size: | Customized/As Per Drawings | Grinding accuracy: | ±0.001mm |

|

|

Japan (SKD11.SKD61.SKH51.S45C) | Tolerance: | 0.001mm |

| USA (AISA.D2.H13.P20.M2) | EDM Accuracy: | ±0.003mm | |

| Germany (DIN.2379.2363.2344.2347) | Grind Clear Angle Max: | 0.02 | |

| ASSAB(Rigor.DIVEAR.Impax.Elmax.VANADIS4.STAVAX) | EDM Angle Max: | 0.02 | |

| Proce | Grinding→Wire Cutting | Grinding Finish Ra: | 0.2 |

| Application: | Hight Plastic Injection Machine Parts | EDM Finish Ra: | 0.3 |

| Wire Cutting Finish Ra: | 0.3-0.4 | ||

| Processing flow: | Heat treatment →Grinding→Wire Cutting→Quality inspection | ||

Specification:

Size tolerance within +/-0.002mm

Axiality within 0.005mm

Surface Roughness within Ra0.6

Verticality within 0.005mm

The multi-cavity is well-matched

Further dimensions,lengths and materials available on request

FAQ:

A:Our factory is located in NO.2,ShangLang Road,XiaBian District,Chang'an town, Dongguan China

All our clients from home or abroad are warmly welcomed to visit us at any time.

Q:When can i get the quotation or the reply on your side?

A: The swift response will usually be taken within 4 hours after we got your inquiry or email.If you are very urgent,please let us know so that we will regard your inquiry priority

Q:Do you provide free sample?

A:Yes,we could offer some samples for free, but freight collect.

Q: How can you ensure the quality of the parts that we ordered?

A: Firstly,the pre-testing will be done before every step,secondly,we'll have the final checking for all the parts before the shipment,So believe that a strict quality control system will ensure you the high quality parts.

Q:What will you do after sales?

A:We have after-sales servise, when you received our products,we will follow up and await your feedback.

Any question related to our products,our experienced engineers are ready to help.

Further Information:

| Testing machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine,roughness tester, hardness tester and so on. |

| QC | 1) Technicians self-check in production |

| 2) Engineer spot check in production | |

| 3) QC inspects after mass production finished | |

| 4) International sales who were trained the technical know-how spot check before shipping | |

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe,South Europe, South Asia, Africa Africa |

Advantages:

1. Good quality

Include machining, surface treatment, specification, packing, etc.

2. Proper suggestions

If you are not familiar with material, surface treatment or something, please tell us your requirement, according to which we will provide you with proper suggestions. Also, advice will be given during machining when your design is found not good enough. Anyway, it is finally up to you whether to adopt the suggestions.

3. Lower cost in machining hardended metal

We've found our way to slow the damage of tool during machining hardended metal, and as a result, the cost decreases.

If you are interested, please do not hesitate to contact us! Thank you!

![]()