-

Plastic Injection Molding Parts

-

Medical Injection Molding Parts

-

Precision Injection Molding Parts

-

Metal Injection Molding Parts

-

Connector Mold Parts

-

Plastic Auto Parts Mould

-

Plastic Injection Machine Parts

-

Injection Molding Automotive Parts

-

Consumer Electronics Components

-

Mold Core Pins

-

Hot Runner Mould Parts

-

Standard Mould Parts

-

Miss JennyI am very satisfied with the quality and delivery time of your company and look forward to long-term cooperation in the future.

-

Mr.t HerryI have visited your company's machinery and testing equipment, and I feel very good. The sample has also been received, the polishing is very beautiful, very good!

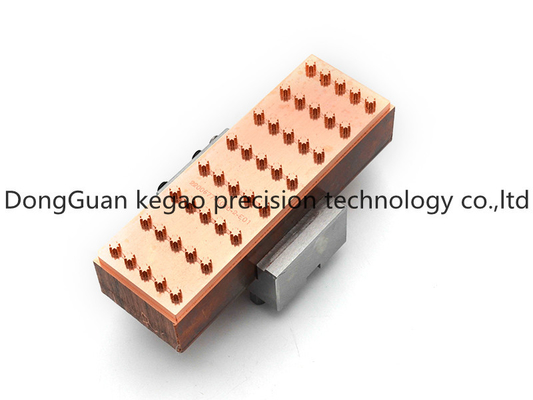

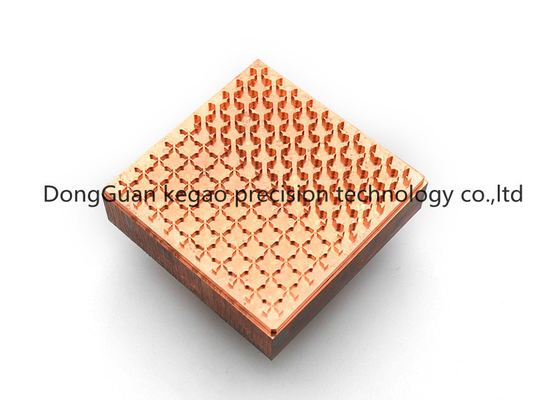

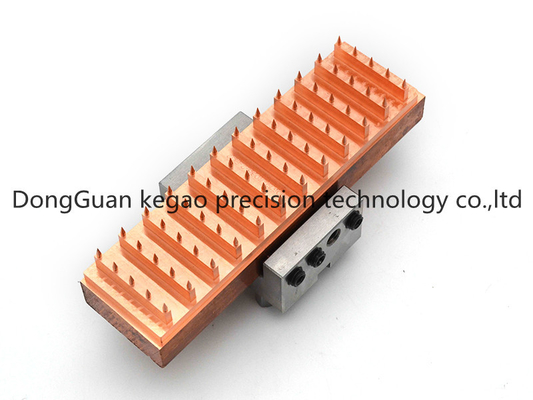

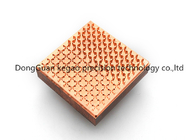

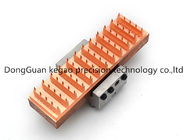

Copper High Precision Electrode Metal Injection Molding Process 35-40 HRC

| Material | Copper | HRC | 35-40 |

|---|---|---|---|

| Advertising | HIGH PRECISION ELECTRODE | Size | Make According To Drawings |

| Heat Treatment | Standard | Surface Treatment | Polishing |

| Export Country | Japan/USA/Europe | Payment Terms | Negotiable |

| High Light | Copper Electrode Metal Injection Molding Process,40 HRC Metal Injection Molding Process,Copper Electrode Metal Injection Molding Parts |

||

MATERIAL COPPER AND HIGH PRECISION ELECTRODE MANUFACTURED IN CHINA

Description:

| Parts Name: | MATERIAL COPPER AND HIGH PRECISION ELECTRODE MANUFACTURED IN CHINA | Hardness: | 35-40 |

| Product size: | Customized/As Per Drawings | Grinding accuracy: | ±0.002mm |

| Japan (SKD11.SKD61.SKH51.S45C) | Tolerance: | 0.01mm |

| USA (AISA.D2.H13.P20.M2) | EDM Accuracy: | ±0.003mm | |

| Germany (DIN.2379.2363.2344.2347) | Grind Clear Angle Max: | 0.02 | |

| ASSAB(Rigor.DIVEAR.Impax.Elmax.VANADIS4.STAVAX) | EDM Angle Max: | 0.02 | |

| Proce | CNC | Grinding Finish Ra: | 0.2 |

| Application: | PLASTIC MOLD COMPONENTS | EDM Finish Ra: | 0.3 |

| Wire Cutting Finish Ra: | 0.3-0.4 | ||

| Processing flow: | Heat treatment → CNC→Quality inspection | ||

We promise all the parts from our company have no sharp edge. All dimensions are controlled according to your drawings. Every product will be fully inspected and carefully packed to prevent the bump and rust in transit. The craftsmanship of all parts we machined is controlled rigorously, every product has its own process card and process chart. Our quality inspection procedure is quite strict,it must self-inspected during production, we have flow inspectors and professional inspectors.

Our Service:

1. Customer's request is our purpose and target.

2. Quick samples delivery service and produce according to your BOM.

3. Professional production team, strictly quality control department, experienced sales department.

4. One-stop solution for our long term customers .

5. Customized size and OEM/ODM service acceptable.

6. 100% inspect before deliver , quality warranty and long term after-service .

7. Competitive price ,Excellent service , Quick delivery , Safety payment , Flexible trade terms.

Sales team:

Only with teamwork can leadership be maintained.

Team spirit is a company’s core competitiveness. Only team can lead the way, only strong team can go further.

Further Information:

| Testing machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine,roughness tester, hardness tester and so on. |

| QC | 1) Technicians self-check in production |

| 2) Engineer spot check in production | |

| 3) QC inspects after mass production finished | |

| 4) International sales who were trained the technical know-how spot check before shipping | |

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe,South Europe, South Asia, Africa Africa |

I think a lot of items will match your interest,and really hope to establish business relationship with you!

Any questions,pls feel free to contact me at any time.

If you are interested, please do not hesitate to contact us! Thank you!![]()

![]()

![]()