|

Attribute Category

|

Detailed Description

|

|

Material Options

|

- Stainless Steel

- Aluminum

- Copper

- Brass

- Carbon Steel

|

|

Fabrication Processes

|

- Laser Cutting

- Bending

- Punching

- Welding

- Shearing

- Rolling

|

|

Surface Finishing

|

- Powder Coating

- Anodizing

- Plating

- Polishing

- Painting

|

|

Production Capabilities

|

- Low to High Volume Production

- Prototype to Mass Production

- Custom Fabrication

|

|

Tolerances

|

- High Precision Tolerances (up to ±0.005 inches)

|

|

Design and Engineering Support

|

- CAD/CAM Design Assistance

- Design for Manufacturability (DFM) Feedback

|

|

Quality Control

|

- Dimensional Inspection

- Material Certification

- Welding Inspection

|

|

Application Areas

|

- Automotive

- Electronics

- Aerospace

- Medical Devices

- Consumer Goods

|

|

Packaging and Logistics

|

- Custom Packaging

- Global Shipping

- Labeling and Barcoding

|

|

Additional Services

|

- Assembly Services

- Rapid Prototyping

- Reverse Engineering

|

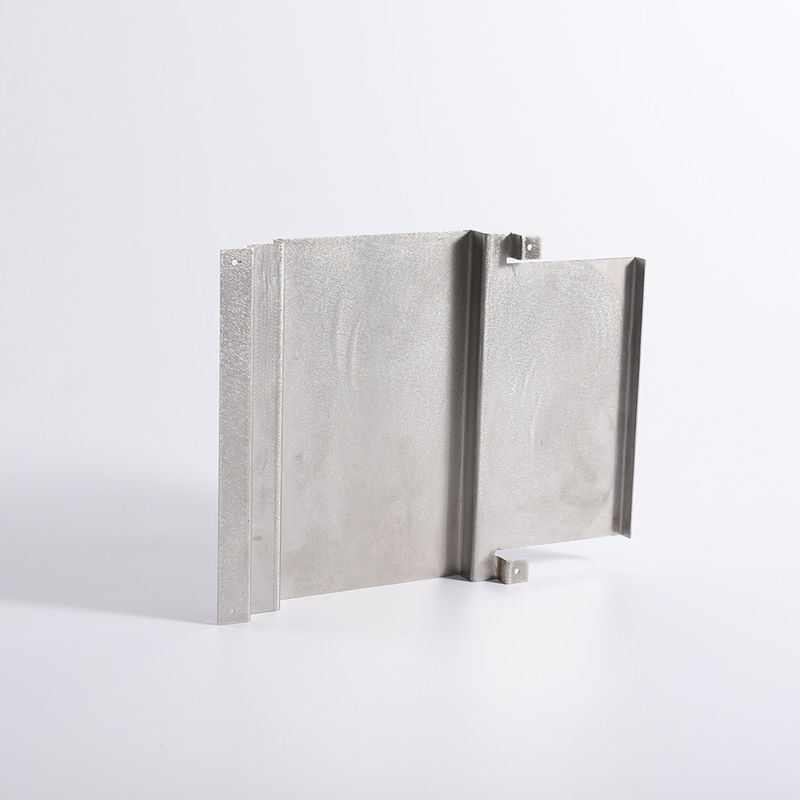

FCE provides comprehensive sheet metal fabrication services, including cutting, bending, stamping, and welding metal sheets to create various shapes and sizes. This service is essential for producing industrial equipment, building components, electronic enclosures, automotive parts, and more. Below is a detailed introduction to our customized sheet metal fabrication service and its advantages:

Our Sheet Metal Fabrication Service Includes:

Design and Engineering Support:

Product Design: FCE assists customers with initial product design to ensure manufacturability through sheet metal processes. We offer personalized design suggestions to meet specific customer needs.

Engineering Drawings: Based on customer requirements, we create detailed engineering drawings that provide the necessary technical details for fabrication, ensuring precision and manufacturability.

Material Selection:According to the product's functional requirements and operating environment, we select suitable materials. Common materials include stainless steel, aluminum, copper, brass, carbon steel, and galvanized steel. We can also recommend and use special materials based on customer needs.

Cutting:Utilizing laser cutting, plasma cutting, and waterjet cutting technologies, we precisely cut metal sheets into the desired shapes and sizes. We can perform custom cutting based on customer drawings or samples.

Bending:Using bending machines, we shape metal sheets into the required angles and forms, establishing the basic outline of the parts. We can perform complex bending processes according to customer design requirements.

Stamping:Employing stamping equipment, we punch, form, and stretch metal sheets to quickly produce complex components. We can perform custom stamping based on customer drawings or samples.

Welding:Connecting different metal parts through welding techniques such as MIG welding, TIG welding, and spot welding to form complete structures. We provide professional welding services to ensure weld quality and strength.

Surface Treatment:Enhancing the appearance and corrosion resistance of products through painting, electroplating, anodizing, brushing, and polishing. We offer various customized surface treatments according to customer requirements.

Assembly and Integration:Assembling and integrating sheet metal parts into final products, followed by necessary functional testing and quality inspection. We provide one-stop assembly services to ensure product integrity and reliability.

Packaging and Shipping:Packaging products according to customer requirements and arranging safe transportation to ensure timely delivery. We offer customized packaging solutions to ensure products remain intact during transit.

Advantages of FCE's Sheet Metal Fabrication Service:

High Precision:Using advanced equipment and technologies to achieve high precision, ensuring that parts meet design specifications. We can meet stringent tolerance requirements.

Flexibility:Capable of producing parts in various shapes and sizes to meet diverse industry and application needs. We can make flexible adjustments according to customer demands.

Rapid Production Cycles:Efficient processes and equipment ensure quick turnaround times, reducing product lead times. We can provide expedited services based on urgent customer needs.

Cost-Effectiveness:High material utilization and lower production costs, suitable for both large-scale production and small-batch customization. We offer competitive pricing schemes.

Structural Strength:Sheet metal parts typically have high strength and durability, able to withstand significant mechanical stress and environmental conditions. We ensure the quality and durability of each product.

Wide Range of Applications:Sheet metal fabrication is widely used in automotive manufacturing, construction, electronics, aerospace, and more, catering to extensive market demands. We provide professional solutions based on customer industry characteristics.

Applications of FCE's Sheet Metal Fabrication Service:

Automotive Manufacturing: Producing car bodies, chassis, engine hoods, and other parts.

Construction: Creating building facades, ventilation ducts, metal roofs, and more.

Electronics: Manufacturing enclosures, cases, control panels, and other components.

Aerospace: Producing aircraft structural parts, engine covers, and cabin components.

Medical Equipment: Fabricating medical device enclosures, brackets, and instrument panels.

In summary, FCE's sheet metal fabrication service offers comprehensive design, production, and quality control support, helping customers efficiently and economically produce high-quality metal products. Whether for mass production or small-batch customization, FCE's sheet metal fabrication service can meet all customer needs. We are committed to providing personalized custom solutions to ensure the satisfaction of every customer.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!