-

Plastic Injection Molding Parts

-

Medical Injection Molding Parts

-

Precision Injection Molding Parts

-

Metal Injection Molding Parts

-

Connector Mold Parts

-

Plastic Auto Parts Mould

-

Plastic Injection Machine Parts

-

Injection Molding Automotive Parts

-

Consumer Electronics Components

-

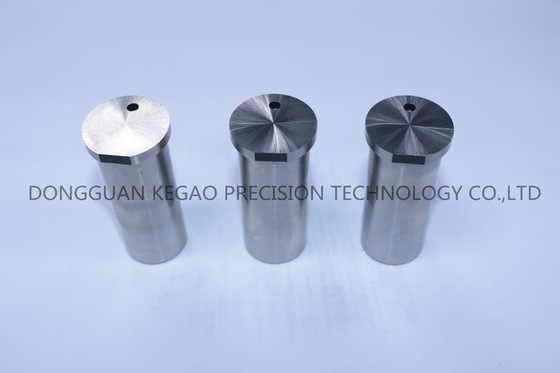

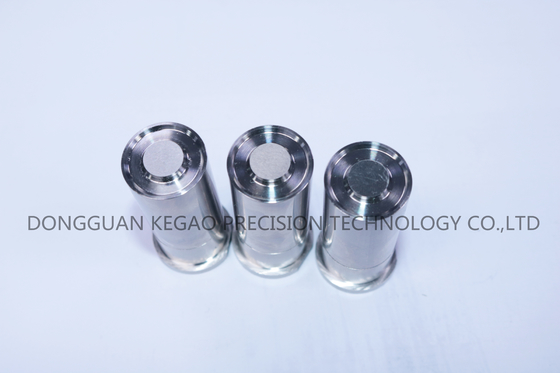

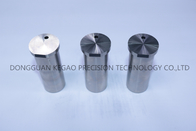

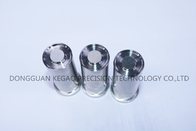

Mold Core Pins

-

Hot Runner Mould Parts

-

Standard Mould Parts

-

Miss JennyI am very satisfied with the quality and delivery time of your company and look forward to long-term cooperation in the future.

-

Mr.t HerryI have visited your company's machinery and testing equipment, and I feel very good. The sample has also been received, the polishing is very beautiful, very good!

SKH51 Mold Core Pins , Core Cavity In Injection Molding DIN S652

| Material | SKH51 | HRC | 60-62 |

|---|---|---|---|

| Advertising | Mold Core Pins For Plastic Injection Molding Parts | Size | Make According To Drawings |

| Heat Treatment | Standard | Surface Treatment | Polishing |

| Export Country | Japan/USA/Europe | Payment Terms | Negotiable |

| High Light | SKH51 core cavity in injection molding,DIN S652 Mold Core Pins,SKH51 Mold Core Pins |

||

HSS SKH51 Material Mold Core Pins For Plastic Injection Molding Parts

Description:

| Parts Name: | HSS SKH51 Material Mold Core Pins For Plastic Injection Molding Parts | Hardness: | 60-62HRC |

| Product size: | Customized/As Per Drawings | Grinding accuracy: | ±0.001mm |

|

|

Japan (SKD11.SKD61.SKH51.S45C) | Tolerance: | 0.001mm |

| USA (AISA.D2.H13.P20.M2) | EDM Accuracy: | ±0.003mm | |

| Germany (DIN.2379.2363.2344.2347) | Grind Clear Angle Max: | 0.02 | |

| ASSAB(Rigor.DIVEAR.Impax.Elmax.VANADIS4.STAVAX) | EDM Angle Max: | 0.02 | |

| Process: | Grinding | Grinding Finish Ra: | 0.2 |

| Application: | Mold Core Pins For Plastic Injection Molding Parts | EDM Finish Ra: | 0.3 |

| Wire Cutting Finish Ra: | 0.3-0.4 | ||

| Processing flow: | Heat treatment →Grinding→Quality inspection | ||

At present we have about 100 experienced processing personnel.

Tolerance:

+-0.005mm, Depends on customer’s requirements.

Drawing Format:

PDF/DWG/DXF/IGS/STEP,etc

Packaging:

Inner packing with recycle plastic box and anticorrosive oil, outer with sponge and PE bags, or as customer's requirements.

Application field :

Automobile parts, medical, daily necessities packaging, cosmetic packaging, etc.

Sales team:

Only with teamwork can leadership be maintained.

Team spirit is a company’s core competitiveness. Only team can lead the way, only strong team can go further.

Advantage:

| 1. Highly polished finish 6-8 micro finish. |

| 2. Precision form ground to close diameter tolerance +/-0.005mm |

| 3. Common fractional sizes available up to 3 1/2″ long. |

| 4. Custom sizes can be made to order up to 1″ diameter. |

| 5. Custom hardness RC 64-65 and triple drawn available on request. |

Service:

1. Providing professional advises and operation.

2. Customer service online with 24 hours.

3. Full inspection on all the products before shipment.

4. Good After-sale service.

5. Strict quality control.

6. Shipping & Price Term: EXW my factory; FOB any Chinese port; CIF any destination port.

7. OEM and ODM are all available.

How to order?

1. We evaluate the drawing and requirement immediately.

2. We try to send the offer at the same day back to customer.

3. If we both agreed on the offer, for trade rules, we accept 50% Deposit before order, and 50% Balance when shipment is taking.Then we can start manufacturing or sample process.

4. Our production time usually takes 10 working days,sample process takes 7 days. It depends on order quanity and product itself.

5. We can ship the parts by express,air,sea according to your need.

Working Procedure:

1. You send us drawing or sample

2. We make the sample and send it to you

3. We start to make the product

4. When the goods is done, we take photoes for your check and you then pay the balance

5. We deliver the products to courier company

If you are interested, please do not hesitate to contact us! Thank you!

![]()