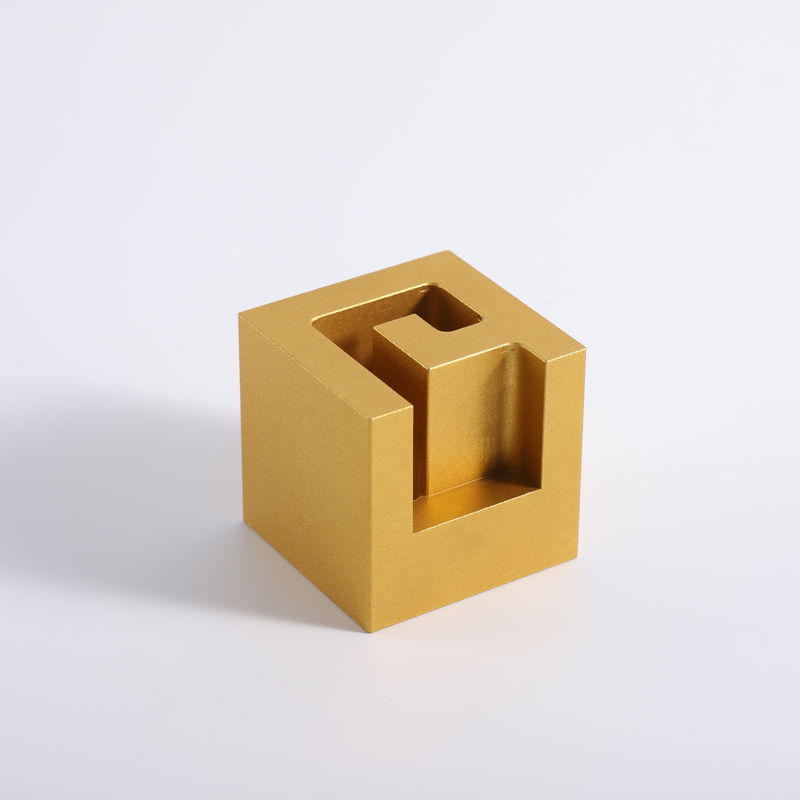

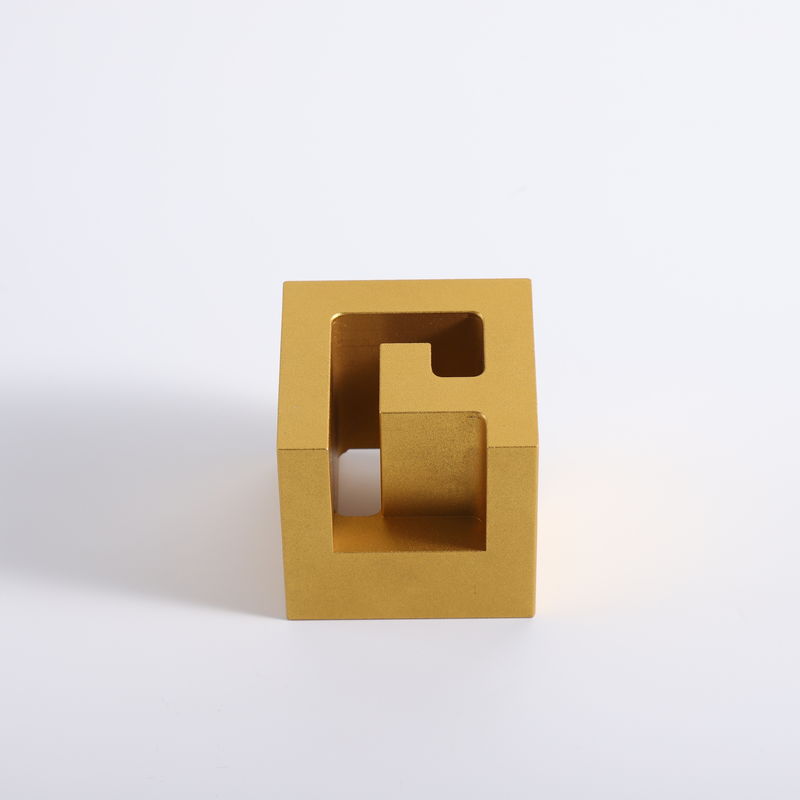

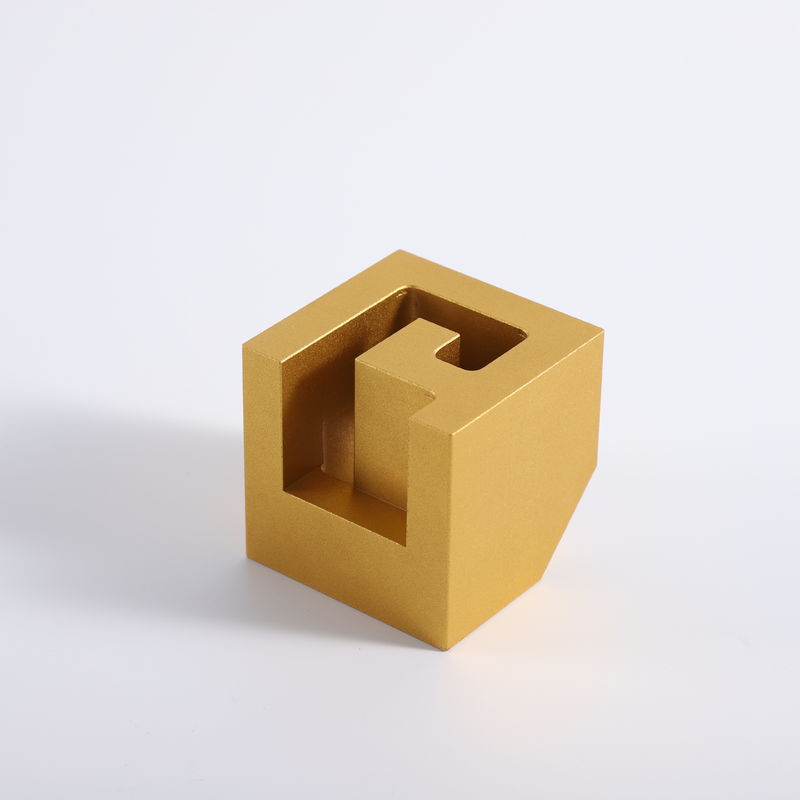

Custom CNC Machining Services for Metal and Plastic Parts

Here is a detailed attribute table for CNC Machining Services:

FCE provides a robust CNC Machining Service designed to deliver swift, high-quality solutions tailored to our clients’ needs. Our service is distinguished by several essential attributes:

Complimentary DFM Feedback and Instant Quotations

At FCE, our experienced team offers free Design for Manufacturability (DFM) feedback, coupled with instant quotations, to ensure your CNC Machining project is launched efficiently and effectively.

Extensive Range of Machinable Materials

Our CNC Machining Service encompasses a wide array of materials, including both metals and plastics, allowing us to cater to a diverse set of machining requirements.

Fast Prototyping Capabilities

With our rapid CNC machining processes, we can produce prototypes within just one day, enabling you to swiftly validate your design concepts.

High-Volume Manufacturing

Our CNC Machining Service is equipped to handle high-volume production, capable of delivering over 1,000 pieces within a matter of days, ensuring that your project deadlines are met.

Comprehensive Order Management

FCE offers a complete order management service for CNC machining, overseeing every phase from initial design to final production, all handled by our skilled team.

Choosing FCE's CNC Machining Service guarantees a professional, fast, and reliable one-stop solution, ensuring that your project is completed

successfully.

Common CNC Machining Materials

Metals:

Aluminum (6061, 7075, 2024): Known for being lightweight, strong, and corrosion-resistant, aluminum is also easy to machine.

Stainless Steel (304, 316, 17-4 PH): Valued for its corrosion resistance, high strength, and heat resistance.

Carbon Steel (1018, 1045): Offers high strength and wear resistance, with the added benefit of being cost-effective.

Brass (C360): Boasts excellent mechanical properties, corrosion resistance, and machinability.

Copper: Renowned for high electrical and thermal conductivity, alongside good ductility.

Titanium (Ti-6Al-4V): Lightweight, strong, corrosion-resistant, and biocompatible, making it ideal for medical applications.

Plastics:

ABS: Offers high strength, good impact resistance, and is easy to machine.

Polycarbonate (PC): Known for its high strength, transparency, and heat resistance.

Nylon (PA): Highly durable, wear-resistant, and provides good self-lubrication.

Delrin (POM): Features high rigidity, wear resistance, and a low friction coefficient.

Polyethylene (PE): Offers good chemical resistance and a low friction coefficient.

Polypropylene (PP): Exhibits good chemical resistance and a higher melting point.

PEEK: Known for its high strength, excellent heat resistance, and chemical resistance.

Composites:

Carbon Fiber: Characterized by its high strength, low weight, and excellent rigidity.

Glass Fiber: Offers high strength, corrosion resistance, and is more cost-effective compared to carbon fiber.

CNC Machining Processes

Milling: Utilizes a rotating tool to remove material, ideal for creating planes, grooves, holes, and intricate shapes.

Turning: The workpiece rotates while a tool removes material, primarily used for cylindrical parts like shafts and discs.

Drilling: A drill bit creates circular holes, extendable to boring and tapping for threaded holes.

Grinding: Employs a high-speed rotating abrasive wheel to achieve high-precision surfaces on hard materials.

Boring: Expands or refines existing holes, ensuring high precision.

Tapping: Cuts internal threads, essential for manufacturing threaded components.

Wire EDM: Uses a thin, charged wire to cut materials with high precision, ideal for complex and hard materials.

EDM: Removes material through electrical discharge, suitable for intricate shapes and hard materials.

Laser Cutting: Melts and cuts materials using a high-energy laser, perfect for precise and complex cuts.

Waterjet Cutting: Cuts materials using high-pressure water and abrasives, avoiding heat-affected zones.

Engraving: Uses precision tools to etch text or patterns on surfaces, commonly for identification and decoration.

Heat Treatment: Alters material properties through heating and cooling to enhance hardness and strength.

Surface Treatment: Includes processes like anodizing, painting, and electroplating to improve appearance, corrosion resistance, and durability.

CNC Machining Applications

CNC Machining is integral across various sectors, providing precision and versatility to meet complex industry demands.

Automotive:

Engine Components: Such as cylinder heads, pistons, and crankshafts.

Chassis & Suspension: Including control arms and structural brackets.

Interior Parts: Such as dashboards and ventilation components.

Aerospace:

Aircraft Structures: Including wing spars and fuselage frames.

Engine Parts: Such as turbine blades and nozzles.

Space Components: For satellites and spacecraft, including shells and brackets.

Medical Devices:

Surgical Tools: Like scalpels and forceps.

Implants: Including artificial joints and dental implants.

Diagnostic Equipment: Housings and internal components for precision devices.

Electronics:

Enclosures & Frames: For computers, servers, and routers.

Cooling Devices: Such as heatsinks and liquid cooling systems.

Precision Connectors: For circuit boards and other electronic devices.

Consumer Goods:

Appliance Parts: Internal components for washing machines, refrigerators, and microwaves.

Sporting Goods: Such as golf club heads and bicycle parts.

Electronic Gadgets: Including smartphone cases and headphone parts.

Energy Sector:

Oil & Gas Equipment: Such as drill bits and pump housings.

Renewable Energy: Components for wind turbines and solar panels.

Nuclear: High-precision parts for reactors.

Industrial Equipment:

Machine Parts: Including tool components and precision jigs.

Conveyor Systems: Rollers and chains.

Automation: Parts for robots and sensor brackets.

Mold Making:

Injection Molds: For producing plastic components.

Stamping Dies: For forming metal sheets.

Casting Molds: For metal casting processes.

Conclusion

FCE's CNC Machining Service is vital in industries where precision, efficiency, and versatility are paramount. Our service meets the diverse demands for high-quality parts across multiple sectors, ensuring that your projects are delivered with excellence and reliability.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!