|

Attribute

|

Description

|

| Design and Engineering |

- Product Design Support: Assistance with initial design for manufacturability. |

| |

- Engineering Drawings: Detailed technical drawings tailored to specifications. |

| Material Options |

- Metals: Stainless steel, aluminum, copper, brass, carbon steel, galvanized steel. |

| |

- Special Materials: Customized material selection based on functional and environmental needs. |

| Cutting Techniques |

- Laser Cutting: Precision cutting for complex shapes. |

| |

- Plasma Cutting: Efficient cutting for thicker materials. |

| |

- Waterjet Cutting: High-precision, no heat-affected zone cutting. |

| Bending and Forming |

- Bending: Creating precise angles and forms with advanced machinery. |

| |

- Forming: Complex shapes and curves according to design requirements. |

| Stamping |

- High-Volume Production: Quick, efficient stamping for complex parts. |

| |

- Custom Stamping: Tailored to customer specifications. |

| Welding |

- MIG/TIG Welding: High-quality welding for robust construction. |

| |

- Spot Welding: Efficient joining of sheet metal components. |

| Surface Treatment |

- Painting: Custom color and finish options for enhanced appearance. |

| |

- Electroplating: Improved corrosion resistance and aesthetic appeal. |

| |

- Anodizing: Durable finish, particularly for aluminum components. |

| |

- Brushing & Polishing: Surface finishing for a professional look and feel. |

| Assembly & Integration |

- Comprehensive Assembly: Integration of sheet metal parts into final products. |

| |

- Functional Testing: Ensuring operational performance before delivery. |

| Packaging & Shipping |

- Custom Packaging: Designed to protect products during transit. |

| |

- Secure Shipping: Safe and timely delivery of products. |

| Precision |

- High Accuracy: Tight tolerances and precision fabrication. |

| |

- Quality Control: Rigorous inspections throughout the production process. |

| Flexibility |

- Custom Solutions: Adaptable production for various shapes, sizes, and volumes. |

| |

- Rapid Prototyping: Quick turnaround for prototypes and short runs. |

| Cost-Effectiveness |

- Optimized Production: Efficient use of materials and processes to reduce costs. |

| |

- Scalable Solutions: Suitable for both large-scale production and small-batch orders. |

| Durability |

- Structural Strength: Ensuring longevity and resistance to environmental conditions. |

| |

- Reliability: Consistent quality across all produced parts. |

| Industry Applications |

- Automotive, Aerospace, Electronics, Medical, Construction, and more: Custom solutions for various industries. |

Sheet Metal Fabrication for Smoodi’s Smoothie Maker: FCE’s Precision and Dedication

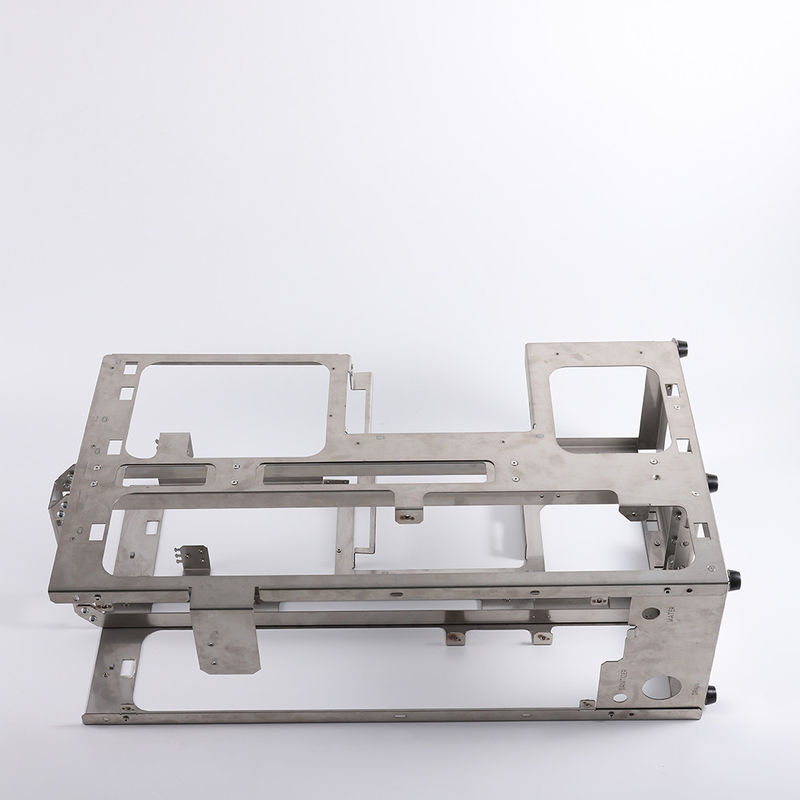

In October 2020, FCE began a collaborative partnership with smoodi, a brand committed to producing green, natural, 100% pure fruit smoothies. To support their product, smoodi required a smoothie machine with a sturdy framework made from sheet metal. This sheet metal framework presented several challenges, including deburring, precision in bending, rivet strength, and assembly accuracy.

Sheet metal fabrication is an intricate process, and to ensure success, FCE carefully broke down each step in detail during the early project phases. We conducted comprehensive engineering and manufacturing feasibility analyses, ensuring that each phase of production was meticulously planned. The processes involved included laser cutting, deburring, bending, riveting, welding, grinding, and powder coating.

Laser Cutting for Precision Using CNC laser cutting, FCE ensured that all sheet metal parts achieved precision tolerances of +/- 0.05mm. This high level of accuracy was essential for ensuring that all components fit together seamlessly during the final assembly.

Deburring for Safety and Assembly Deburring was a key focus in this project. To ensure that the assembly process was safe for our employees and that all parts fit together perfectly, we custom-built a deburring machine specifically for smoodi's components. This step was crucial for eliminating sharp edges and ensuring the safety of handling during assembly, while also enhancing the quality of the final product.

Accurate Bending with CNC Press Brake We used a CNC press brake to ensure precise bending of the sheet metal parts. Accuracy in bending was vital for maintaining the overall tolerances of the assembled unit. After bending, we conducted thorough checks to ensure that the tolerance of the final assembly met the required specifications, guaranteeing precision in the overall structure.

Riveting and Strength Testing The riveting process required testing various rivet materials and different levels of force. We also tested multiple rivet hole sizes to find the perfect fit with the rivets. After extensive testing, we finalized the rivet type and hole size, ensuring that each rivet was securely fastened to the sheet metal, providing the necessary strength for the machine’s frame.

Welding and Surface Finishing For welding, we employed different techniques depending on the material, including stainless steel 304 and aluminum 5052. After welding, the seams were ground down to ensure they were smooth and even, with both precision and flatness meeting the client’s requirements.

Environmentally Friendly Powder Coating The final step was to apply an eco-friendly powder coating to the outer surfaces of the machine. This coating not only enhanced the appearance of the machine but also ensured an even and durable finish, perfectly aligned with smoodi’s sustainability goals and high-quality standards.

Success in the Market smoodi has since launched the smoothie machine in the market, and the feedback from customers has been overwhelmingly positive, with no reported after-sales issues. FCE played a crucial role in this success, serving as a key partner and supplier. Our focus on precision sheet metal fabrication, particularly in the deburring process, contributed significantly to the quality and performance of the final product.

As a trusted manufacturing partner, FCE continues to deliver high-quality, reliable solutions, ensuring that our clients can confidently bring their products to market with exceptional results.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!